Pushing standards to new heights

Proven innovation

INTUITIVE

Reach truck drivers are often the best-qualified operators in your team. We help to make their life easier, safer, and more comfortable with a newly designed, ergonomic, and functional driver's compartment.

INTERACTIVE

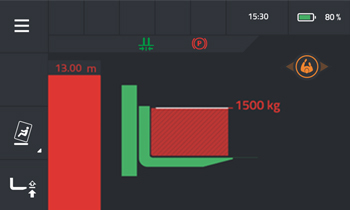

The new and unique interactive touchscreen has various functions like speed control, lift height, and warnings for overload.

INTELLIGENT

Our analytics of 10.000 connected trucks proved that Lithium-ion batteries meet reach truck applications demands. So we offer you the choice between 3 energy packs to find the one that fits your operations. A responsible decision for your life cycle cost, productivity, and the environment.

INSIGHT

You can reach new levels in safety, productivity, and efficiency with the BT Reflex smart trucks as standard. Letting only authorised drivers start up the machine in a safe way, and making it easy to connect with I_Site fleet management from Toyota.

Intuitive driver experience

Lean back, look up

No two drivers are exactly the same, so we set out to design a solution that would be exactly the right height and angle, no matter who’s driving.

For maximum visibility, there is an optional panoramic glass roof. The unique tilting cabin on E-series models is a proven innovation reducing strain. A happy driver is a productive driver.

Next level comfort

The new optional air-suspension seat makes sure drivers can comfortably do the heavy lifting. The cabin floor height can also be easily adjusted at the touch of a button further improving driver ergonomics.

At your fingertips

The new Reflex features a new right-hand control unit letting drivers choose either a mini-joystick control or multi-function control, according to driver preference.

The essentials

Additional storage, a mobile phone charging point, and even an optional integrated Bluetooth speaker in the roof so you can listen to your favourite music all shift long.

Interactive touchscreen

Access control

The new touchscreen provides easy interaction between truck and driver. Meaning a higher level of safety and productivity. With a pin code or access card, you secure that only authorised drivers can operate the truck.

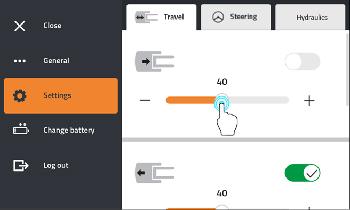

Drive control

Not only the essential pre-operational check is included in the new touchscreen interface but also other safety features such as automatic speed control, fork levelling, and centering. Safety first!

Lift mode

While lifting the load the drivers will get continuous updates on lift height, load weight, and fork alignment as well as more critical alerts like overload warnings.

Customise settings

The touchscreen allows you to control settings such as lift height limits and height pre-selection, and other performance parameters important for your operations.

Intelligent energy packs

Li-ion: The way to go

Perfect fit

Analytics of 10.000 connected trucks prove that lithium-ion is the preferred energy solution to fit the most intensive reach truck applications. A perfect fit for both you and the environment.

Double the life time

As with all lithium-ion-based energy systems, it's maintenance-free and less daily care. This gives a higher lifetime which meets the truck life cycle. The working range will depend on the level of charging that takes place during working breaks.

3 different sizes

Good charging disciplines can enable trucks with even the smallest energy pack to work around the clock. But for maximum flexibility, we offer 3 different options

- Standard Pack

- Intensive Pack

- Max Pack

Insights with I_Site

Only authorised drivers

Creating unique driver profiles with PIN code in the I_Site portal ensures only trained and authorised drivers have access and can operate your machines. Or you can use Smart Access cards, nicely integrated into the driver interface.

Increase safety

Pre-operational check is a smart I_Site feature that is included in the driver interface to make sure an automated check is done by your drivers before every shift – improving reliability and safety.

Messages via the truck

This I_Site feature allows for easily sending of messages to and from the truck via the new driver interface. For example, the driver can send an alert in the event of a problem, and a service technician can send a message to the driver to request a return to base.

Manage impacts

Shock sensors on the truck provide information on collisions. Insights via I_Site fleet management on the incident and driver can help to prevent and avoid damage to your connected smart trucks and infrastructure – for a safer and more cost-efficient operation.

Meet the new Reflex family

German Design Award Gold for Reflex E-series

“Designed for work in high-bay warehouses, the BT Reflex E-series reach truck impresses with an outstanding overall design concept in a design language that has been reduced down to the very last detail. Product usability and dynamism are congenially combined in an impressive manner in this product.”

German Design Award jury

Do you want to know more?

FAQ

Reach trucks are forklifts that offer high lift heights and high maneuverability in narrow aisles thanks to its ability to reach out the mast.

A reach truck can reach out the mast and pick up a pallet in front of the truck and then reach the pallet in again to obtain a small truck width with high stability and high maneuverability.

Lithium-ion batteries provide a wide variety of efficiency advantages, from consistent power delivery to faster-charging capabilities. At Toyota, we offer different energy packs to fit your operations and charging habits.

A lithium-ion battery lasts up to 5,000 charges, while a lead-acid battery lasts about 1,500 times.

Depending on the model, mast heights can reach up to about 13 meters with a maximum lifting capacity of up to 2.5 tonnes.

We have reach trucks for every application. You can find models for more straightforward application, more intensive stacking at height, with tilting cabin, for indoor and outdoor application, multi-directional, with narrow chassis and even cold storage application.

There are many different reach truck specifications to choose from depending on the required capacity and what type of load you handle. Contact your local salespeople for the best suitable specification and then the best price, either for purchase or for rent on short or long term.

With a good charging discipline, you can normally work around the clock with a lithium-ion-powered truck.

Common reach truck application areas are daily goods distribution in large warehouse centers, including frozen areas, manufacturing industries, garden & landscape business, farm industry, beverage, …

Our reach trucks are versatile machines but the best option to work inside as well as outside with our Reflex O-series equipped with elastic tyres to work on all types of floor.

With an optimum balance between operation and opportunity charging, a lithium-ion battery is worth the cost both from a sustainable and financial point of view.

Adapt it for cold store

Managing the cold

To ensure performance in cold environments, BT Reflex R-E-N series are adaptable for cold store operations.

Same performance

With a power unit adapted for cold store applications the BT Reflex will let you lift your load as high as in normal temperature.

Protecting the driver

With the optional heated cold store cabin, the driver is fully protected from the cold down to -30°C.

Great visibility

Thanks to the cabin’s transparent roof and door, safety and high visibility is guaranteed.

Want to see more?

View the BT Reflex presentations by our experts in full screen.

Introducing the product and its innovative features

Insights about the intelligent energy packs

All about the new touch screen

Download

A great driver experience with the new operator compartment

The power of connected trucks

Smart servicing for maximum truck uptime